Exploring Different Types of Power Tools: A Comprehensive Guide

Whether we’re crafting a piece of furniture with care, completing a home renovation project, or building constructions that stand the test of time, the chorus that hums through these tasks is often power tools. These gadgets of modern ingenuity have revolutionized the efficiency and the precision with which tasks can be accomplished in a plethora of industries and DIY projects. This comprehensive guide dives into the various types of electric power tools, distinguishing the essentials from the niches, and sheds light on which could be the perfect gear for your next undertaking.

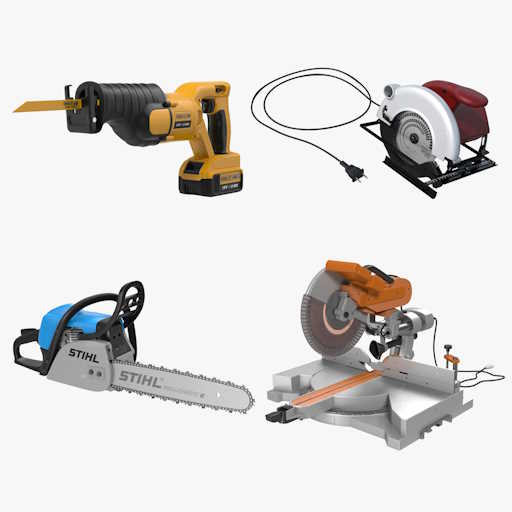

Chapter 1: Common Power Tools

Essential Power Tools for Everyday Projects

When tackling a variety of tasks, whether as a do-it-yourself enthusiast or professional tradesperson, certain power tools have become ubiquitous for their utility and versatility. Below is a list of common power tools that one should consider for their arsenal:

- Cordless Drill: A staple in any toolkit, the cordless drill makes holes, drives screws, and even mixes paint with ease.

- Circular Saw: For precise straight cuts across various materials, a circular saw is a necessity for carpentry and other woodwork.

- Jigsaw: Ideal for cutting curves and complex shapes in wood, the jigsaw is a versatile tool for detailed work.

- Reciprocating Saw: Known for its demolition capabilities, this powerful saw can cut through wood, metal, and PVC.

- Power Sander: Say goodbye to laborious hand sanding. A power sander smooths surfaces quickly and efficiently.

- Impact Driver: A complementary tool to the drill, an impact driver offers higher torque for driving screws and bolts.

- Angle Grinder: For cutting, grinding, and polishing materials, the angle grinder is unmatched in its power.

- Rotary Tool: For engraving, carving, and finishing touches, the rotary tool provides high precision and control.

- Table Saw: A larger investment, the table saw ensures precise cuts on large sheets of material and is a centerpiece in many workshops.

The above list highlights the versatility and importance of having reliable power tools to hand, for tasks both large and small. Whether a beginner or seasoned professional, equipping oneself with these tools can significantly escalate the quality and efficiency of work.

Drills

A quintessential part of any toolkit, drills come in various configurations, from the humble hand drill to the mighty hammer drill, each designed for its own set of activities. The hand drill is the jack of all trades that can serve you well in everyday needs such as putting up shelves or odd repair work. As you progress into heavier work, a corded drill might become your trusty companion, and for intense jobs like masonry, a hammer drill’s pulsating power might be the only way forward.

Saws

Power saws are pivotal to any kind of cutting work, and their variations are vast, providing a solution for every conceivable cutting requirement. Starting with circular saws and reciprocating saws for straight cuts and demolition, to band saws that offer curved precision, selecting the right saw could mean the difference between a masterpiece and a misstep.

Sanders

Smooth surfaces are the sign of a well-prepared project, and sanders are your gateway to such perfection. Belt sanders for quick stock removal, orbital sanders for ultra-smooth surfaces, and detail sanders for those hard-to-reach corners; these tools are the epitome of finesse meeting function.

Impact Drivers

Impact drivers are not just glorified screwdrivers; they are muscular powerhouses that pack a punch with their high torque output. This tool is specially engineered to handle long screws and tough fastening jobs with remarkable ease. Unlike regular drills, impact drivers use a combination of rotational force and concussive blows to drive screws through dense materials without stripping screw heads. They are compact, lightweight, and often come with a hex chuck to accommodate a wide array of driver bits. For any substantial project that involves a lot of fastening, particularly where precision and staying power are required, an impact driver is an invaluable addition.

Grinders

From shaping and cutting to polishing and sharpening, grinders are the do-it-all when it comes to altering materials. Bench grinders are the go-to for sharpening household tools, angle grinders are the versatile workhorses for cutting and grinding, and die grinders cater to finer detail, especially in metalworking.

Table Saws

Fulfilling a pivotal role in workshops, the table saw is an indispensable power tool for precise and efficient cutting of large materials. Its high-powered rotating blade emerges through a flat surface, allowing for straight, smooth cuts with unparalleled accuracy.

Ideal for handling sheet materials like plywood or MDF, a good table saw can offer clean rips, crosscuts, and even bevel cuts, thanks to its adjustable blade. With additional accessories like fences for rip cuts and miter gauges for crosscuts, the table saw is an excellent investment for those looking to undertake extensive woodworking projects, cabinetry, or furniture making.

It is a trusted companion for professionals and serious hobbyists who require consistency and reliability in their craft.

Chapter 2: Specialized Power Tools

Jigsaws

For the artist embedded within the handy person, jigsaws allow for intricate and artistic cuts in various materials. Their ability to cut curves and complex shapes makes them indispensable for creative tasks or tailored designs in wood, metal, or plastic.

Rotary Tools

Think of a rotary tool as a handheld swiss army knife of the power tools world. With the ability to change heads for tasks as diverse as sanding, cutting, carving, and even engraving, these tools provide a high level of control and are perfect for detail work in small areas.

Planers

When it comes to achieving uniform thickness and a smooth finish, especially in woodworking, planers are the tool of choice. Handheld power planers and benchtop models both excel at making boards of lumber consistent, ready to be used for any application.

Nail Guns

The age-old practice of hammering in nails is streamlined and accelerated with nail guns. Framing, finishing, roofing, or even crafting, nail guns come in different types that provide the right velocity and nail types for specific uses, ensuring a professional touch in a fraction of the time.

Routers

When it comes to precision woodworking and decorative finishes, routers are unparalleled. These versatile power tools are essential for adding intricate patterns, shaping edges, hollowing out grooves, or creating joints in wood. With various bits and attachments, routers can transform a plain piece of wood into a work of art or a perfectly functional piece of furniture.

They are also indispensable for tasks such as cutting dadoes, rabbets, and mortises or for adding a professional touch to cabinetry and custom carpentry. Whether for professional woodworkers or hobbyists tackling DIY projects, routers offer the precision and finesse necessary to elevate the craft.

Chop Saws

Chop saws, often referred to as miter saws, stand out as the quintessential tool for making precise crosscuts and miter cuts in a swift motion. These power tools come equipped with a mounted circular saw blade on a swinging arm, allowing for angled cuts to be made with exactitude.

Ideal for framing, molding, and various woodworking projects, chop saws enable users to produce accurate repeat cuts with ease. Their ability to pivot and adjust to different angles makes them indispensable for tasks requiring complex joinery or a polished finish. Whether it is baseboards or crown molding, the chop saw is a reliable tool that ensures a sharp, clean cut every time.

Drill Press

The drill press stands as a paragon of precision and power in the realm of drilling tools. Equipped with a fixed stand and an adjustable table, this robust machine allows for holes to be drilled with remarkable accuracy and consistency. Unlike hand-held drills, the drill press uses a mounted drill bit and lever-controlled spindle to achieve perfect perpendicularity and depth for each hole drilled, an indispensable quality for joinery and metal work.

With its ability to handle a variety of drill bit sizes and types, the drill press is essential for projects that demand exact hole placements, such as furniture making, metal fabrication, and intricate woodworking. The drill press is not only about precision; it also offers the advantage of freeing up the user’s hands, thus enhancing safety and allowing for secure holding of the work piece.

Chapter 3: Corded vs. Cordless

Breaking down the power play, corded tools draw their strength from a relentless power source, ensuring uninterrupted and consistent performance. On the other hand, cordless tools offer a higher degree of mobility and freedom from the constraints of a wire, relying on rechargeable batteries for juice.

Corded tools are typically more powerful and have a continuous workflow advantage. In contrast, cordless tools appeal to those who require on-the-go power solutions, especially for lighter tasks or work in tricky locations where a power outlet isn’t available. They are portable power tools and for most of us these days are generally considered power tools.

Chapter 4: Power Source Options

It’s not just a battle between corded and cordless – power tools also come with other unique energy means. Electric tools are the most common and easily accessible, offering a good combination of power and convenience. Pneumatic tools, powered by compressed air, are known for their high power-to-weight ratios and are popular in workshops and industries.

Battery-operated tools, increasingly powered by lithium-ion these days, combine mobility with decent power, making them a preferred choice for handymen, contractors, and DIYers alike. Hydraulic tools round off the quartet, finding their specialty in heavy industrial work and in instances where extreme conditions are the norm.

Chapter 5: Battery Management for Cordless Tools

In the realm of cordless power tools, battery management is a critical aspect that can greatly influence efficiency and longevity. Proper care and handling can ensure that your lithium-ion batteries maintain optimal performance over their life cycle. It involves regularly checking for damage or deformities, storing batteries at room temperature, and avoiding leaving them on the charger once fully charged.

Additionally, using a smart charger that prevents overcharging and using the batteries regularly can help maintain their health. Recharging before they’re completely depleted also extends battery life as deep discharging can be harmful. By adhering to these best practices, users not only guarantee a longer lifespan for their batteries but also a reliable and steady power supply for their assortment of cordless tools.

Chapter 6: Safety Measures

Any equipment that harnesses energy or uses an electric motor can be a potential hazard, which is why safeguarding yourself should never be an afterthought. Always equip yourself with the appropriate personal protective equipment (PPE), understand how to use the tool through and through, and meticulously adhere to safety protocols and guidelines.

I made a mistake with a circular saw and I now have a seven inch scar in my right leg which took 198 stitches to put back together. It happened very quickly. Be sure you understand and utilize all the safety features of your power tools.

Protective Gear

Eye protection in the form of safety glasses or goggles is a mandatory first step. From sawdust to sparks, the eyes harbor danger from all angles. Earmuffs or plugs are crucial to protect against hearing damage, especially with the high decibel ratings of some power tools.

Handling and Maintenance

Always grip the tool firmly and securely, away from moving parts, and never override safety features. Keep tools clean and well-maintained – after all, a tool that malfunctions mid-use can be just as dangerous as one used carelessly.

Conclusion

Navigating the sea of the different types of power tools can seem an overwhelming task, with the sheer variety catered to every possible task. As you chart your course through projects and professions, remember to select the right tool not just for the immediate task but the safest and most efficient means of completing the job. The right power tool is not just a means to an end, it is a safeguard and a path to your creativity and productivity.

Frequently Asked Questions (FAQs)

What are chop saws primarily used for?

Chop saws are designed for making quick, precise cuts in a variety of materials. They are primarily used for cutting framing materials, molding, and other woodworking or metalworking projects that require sharp, accurate repeat cuts.

How does a drill press differ from a handheld drill?

A drill press provides superior accuracy and power for drilling holes. It’s designed for stationary use and can handle larger and more varied drill bits, allowing for more precise holes drilled perpendicularly and consistently, which is essential for some woodworking and metalworking applications.

When should I choose corded tools over cordless?

Corded tools are generally more powerful and offer continuous use without the need to recharge batteries, making them ideal for complex, long-duration tasks. Cordless tools are more suited for jobs that require portability and access to areas without ready access to power outlets.

What power source is best for my power tools?

The best power source depends on the specific needs of your project. Electric tools provide ease of use; pneumatic tools offer high power-to-weight ratios; battery-operated tools offer portability; and hydraulic tools are best for heavy industrial work.

How can I extend the life of my cordless tool batteries?

To extend the life of your lithium-ion batteries, avoid leaving them on the charger once fully charged, store them at room temperature, prevent overcharging by using smart chargers, and try to recharge them before they are completely depleted.

What safety measures should be taken when using power tools?

Always wear the appropriate personal protective equipment (PPE), including safety glasses and hearing protection. Be sure to understand the tool’s operation fully before use, grip the tool securely, maintain the tool properly, and never remove or tamper with safety features.