The Table Saw Tutorial for DIY Enthusiasts

Woodworking can be one of the most rewarding DIY pursuits. Yet, at the same time, it commands a level of precision and focus that can be daunting, especially for novices. The table saw, a centerpiece in any woodshop, is a powerful tool that embodies this delicate balance of precision and potential danger. Many think of it as the king of the power tools. This guide is an essential read for any woodworker, new or experienced, who wants to master the craft of using a table saw safely and effectively.

Understanding the Basics of How to Use a Table Saw

Before you even think about making cuts, it’s crucial to have a firm grasp of what a table saw is and its capabilities. A table saw consists of a circular saw blade, mounted onto an arbor, that is powered by an electric motor. The blade protrudes through the surface of a table, which provides support for the material being cut. The primary uses of a table saw include cross-cutting, ripping materials to width, and beveling edges. This tool forms the foundation of many woodworking projects due to its precision and ability to handle large pieces of wood.

Prioritizing Safety When Using a Table Saw

Accidents at a table saw can be severe, making safety the unwavering priority each time you turn on the machine. Here are key steps to ensure your safety:

Attire and Equipment

Always wear safety glasses to protect your eyes from splinters and dust.

Consider using hearing protection as table saws can be loud.

Avoid loose clothing and jewelry that could get caught in the blade.

We also recommend the use of a dust mask to protect your lungs from sawdust.

The Work Area

Clear your workspace of any clutter or tools not in use.

Ensure the flooring is solid and won’t shift during operation.

Operating Procedures

Learn the emergency stop features of your saw and do not operate without them in working order.

Avoid reaching across the blade, and never remove the blade guard unless absolutely necessary for a cut.

Respect the kickback zone; this is where wood can unpredictably rise or propel back.

First Aid and Emergency Measures

Have a first aid kit readily available in your workspace.

Know where the nearest phone or emergency services can be accessed.

Getting to Know Your Table Saw

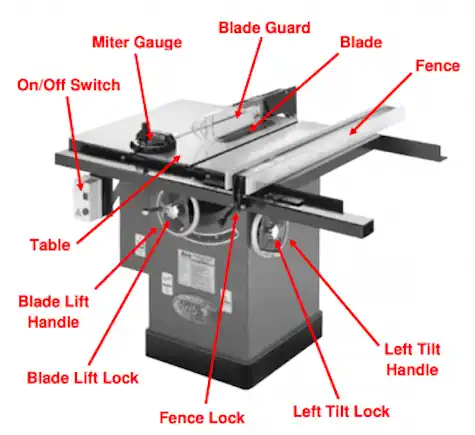

The first step to mastering your table saw is to understand its parts and their functions.

The Table Saw Blade

The heart of the table saw are the saw blades. They are often carbide-tipped for durability and precision.

The Fence

The fence is a straight guide that helps you make consistent rip cuts along the length of the material.

The Miter Gauge

This tool helps guide the material precisely through the blade for cross-cutting.

The On/Off Switch

Know where it is and how to safely use it. Some saws have paddle or knee switches for convenience.

How to Make Simple Cuts on a Table Saw

Starting with the basics, making a straight cut is often the first operation new woodworkers will come across.

Step 1. Set the Blade Height

The general rule is to have the blade extend 1/8″ above the piece being cut or the gullets of the tooth. The depth gauge adjusts the blade height so it can cut a groove or rip through inches of material. Always adjust the blade height to the ideal depth so it fits the material being cut.

Step 2. Adjust the Rip Fence

Slide the rip fence to the desired position for the width of the cut, and use an appropriate push stick to guide the material through.

Step 3. Push Through the Cut

With the power off, align the material to the fence using the miter gauge if cross-cutting, then turn on the saw and push the material through the blade. Sliding the material along the miter gauge should be smooth and easy. Always use a push stick or guide. You should be able to push the wood with one hand and guide it with the other.

Advanced Techniques for the Ambitious Woodworker

For those looking to extend their capabilities, here are some advanced operations to consider.

Bevel Cuts

Adjust the angle of your blade to create cuts with a slope, often needed for box corners or decorative edges. Some angles are preset to make selecting them quick and easy.

Miter Cuts

Use a miter gauge and adjust the angle to create miter joints, commonly seen in frames.

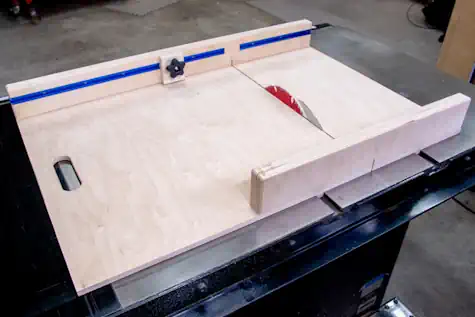

Using Jigs and Sleds

Jigs and sleds are additional tools you can create or buy to make complex cuts, such as dadoes and tenons. Jigs and sleds are typically set on top of the sawing surface and help with alignment and spacing for special or repetitive cuts.

Maintaining Your Table Saw

Regular maintenance is the best way to ensure a healthy, operational table saw that will serve you for years.

Cleaning

After each use, remove dust and debris from your table saw. Use a brush or compressed air to clear the mechanisms.

Alignment

Check the alignment of the blade and fence to the miter slot. Misalignment can lead to dangerous kickback. Properly aligned and the blade serves up clean and precise cuts everytime.

Lubrication

Consistently lubricate any moving parts according to the manufacturer’s recommendations. Keeping a log is recommended to ensure lubrication is performed as recommended. If the saw has sat for a long time, lubrication before use is also highly recommended.

Electrical Safety

If your saw needs to be plugged in, ensure that the cord is not frayed or damaged.

Conclusion: Table Saws as the Cornerstone of Woodworking

A table saw is an indispensable tool for any woodworker. Safety and understanding the basic components are the bedrock of a healthy relationship with this machine. As you grow in your woodworking skills, the versatility of a table saw will continuously offer you new challenges and opportunities. Remember, every table saw cut has the potential to be both beautiful and dangerous. Always handle your saw with vigilance, respect, and the understanding that your safety takes precedence over all else. Happy cutting!

Frequently Asked Questions (FAQs)

What is the best table saw for beginners?

The best table saw for beginners is one that balances safety features, ease of use, and affordability. Look for saws with clear safety instructions, built-in safety mechanisms like blade guards and anti-kickback pawls, and a reputation for reliability. Models from reputable brands that offer instructional resources or customer support are also beneficial for those just starting out.

How often should I maintain my table saw?

Regular maintenance is crucial to keeping your table saw in optimal condition. A general rule of thumb is to clean the saw after each use, check the alignment monthly or before starting a precision project, lubricate moving parts every six months, and inspect the electrical cords and hardware for wear and tear regularly.

Can I make all types of cuts with a basic table saw?

A basic table saw is capable of making a wide variety of cuts, including rip cuts, crosscuts, and bevel cuts. However, for more advanced cuts like dadoes and non-standard miter cuts, additional accessories or jigs may be required. It’s also important to note that the size and power of the saw can limit the thickness and type of materials you are able to cut.

What should I do if my table saw starts making unusual noises or vibrations?

Unusual noises or vibrations can be a sign of a misaligned blade, a dull blade, or a more serious mechanical issue. First, turn off and unplug the saw for safety. Check the blade alignment and sharpness, and inspect for any visible damage. Also, check the balance of the table saw.

An unbalanced table saw will shake or cause the blade to spin out of balance which will result in an odd vibration and an uneven cut. If the problem persists, consult the manufacturer’s guide or seek professional help to avoid risking safety or further damaging the saw.

How do I know if a blade is dull and needs to be replaced?

A dull blade will require more effort to push the material through and may burn the wood or leave rough, uneven cuts. You might also notice more chipping or splintering than usual. Inspect the blade for visible signs of wear, such as missing teeth or a lack of shine on the cutting edges. Regularly inspecting and replacing the blade when necessary ensures cleaner cuts and safer operation.

Can I use accessories not specifically made for my model of table saw?

While it may be tempting to use accessories not specifically designed for your model of table saw, it’s important to prioritize compatibility and safety. Using incompatible accessories can increase the risk of accidents and may void your warranty. Always check with your saw’s manufacturer or consult the user manual to determine which accessories are safe and recommended for use with your specific model.